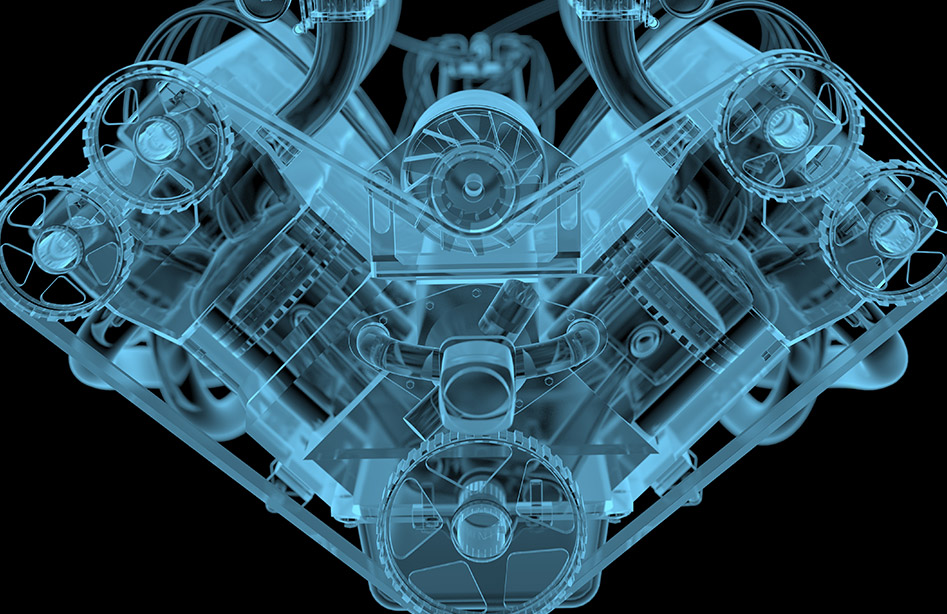

Gulmay x-ray generators and sub-systems are used extensively by the world’s largest industrial OEM manufacturers in a wide variety of non-destructive testing applications.

Non Destructive Testing (NDT) is a crucial technique used across various industries to inspect the internal structure of objects without causing damage. X-ray NDT utilises X-rays to penetrate materials and provide images or data about their internal features, such as defects, cracks, voids, or inconsistencies in composition.

Principle applications that fall within the category of Non Destructive Testing include:

Industrial Manufacturing

X-ray NDT is extensively used in manufacturing industries such as aerospace, automotive, electronics, and engineering. It helps ensure the quality and integrity of critical components such as welds, castings, and assemblies. By detecting defects early in the production process, manufacturers can prevent costly rework or failures in the field.

Weld Inspection

Welds are crucial in various industries, and their integrity is paramount for safety and performance. X-ray NDT allows inspectors to examine welds for defects like cracks, porosity, lack of fusion, and incomplete penetration. This ensures that welded structures meet required standards and specifications.

Quality Control

X-ray NDT is an essential tool for quality control processes. It helps identify manufacturing defects, material inconsistencies, or assembly errors that could compromise the performance or safety of finished products. By conducting thorough inspections using X-rays, manufacturers can maintain high product quality and reliability.

Material Analysis

X-ray NDT is used for material analysis to determine the internal structure, composition, and thickness of materials. It is particularly useful for inspecting complex materials such as composites, ceramics, and alloys. By analysing X-ray images, engineers can assess material properties and make informed decisions about material selection and usage.

Gulmay x-ray generators and sub-systems are used extensively by the world’s largest industrial OEM manufacturers in a wide variety of non-destructive testing applications.

With output power ranging from 50kV to 550kV and 640W to 4.5kW in both unipolar and bipolar configurations, Gulmay’s unique product flexibility means there is a generator ideally suited to every NDT x-ray inspection demand.

From the FC series generators used by the world’s leading tyre manufacturers to the latest in fast rise and slew rate generators for high-speed digital and CT applications, our x-ray generators deliver the perfect solution to meet the needs of today’s most demanding NDT applications.

Other NDT XRay Applications

- Advanced Manufacturing

- Aerospace

- Automotive

- Digital Radiography

- Industrial X-Ray Inspection Systems

- Metrology & Calibration

X-ray Generators for NDT Applications

x

FC Series

FC generators are ideal for low powered NDT applications such as tyre and food inspection.

CF Series

CF generators are designed to work with HP series x-ray tubes and are the perfect choice for CT and digital imaging applications.

CP Series

CP generators continue to provide a reliable and dependable solution for a wide range of high powered NDT applications.

GX Series

GX generators offer the latest in high frequency x-ray generator design for high powered NDT applications.