Why Electronics Industry Microfocus Inspection?

Electronics manufacturers face unique challenges in ensuring that every part, from tiny bonding wires to intricate circuit layouts, meets rigorous standards. Microfocus X-ray inspection allows for high-resolution imaging of critical internal components, detecting defects that may otherwise go unnoticed. Gulmay’s electronics industry microfocus inspection technology provides manufacturers with a powerful, non-destructive method to assess and verify product quality, ensuring reliability in even the most demanding applications.

Circuit Board and SMT Inspection

Surface Mount Technology (SMT) and circuit board inspection are essential in detecting common issues such as voids, bridging, and misalignment. Gulmay’s microfocus X-ray systems provide high-resolution imaging to assess surface-mounted components, solder joints, and connections on printed circuit boards. With electronics industry microfocus inspection, manufacturers can ensure the integrity and precision of SMT assemblies and circuit boards, improving overall product quality and reducing failure rates.

PCBA Electronic Manufacturing and Solder Joint Integrity

Printed Circuit Board Assembly (PCBA) manufacturing involves complex soldering processes, and the quality of these joints directly impacts the reliability of the end product. Gulmay’s microfocus X-ray systems offer precise imaging to assess solder joint quality, detecting issues like voids, cracks, and cold solder joints. Electronics industry microfocus inspection ensures that each connection meets industry standards, providing confidence in the durability and performance of PCBA electronic manufacturing outputs.

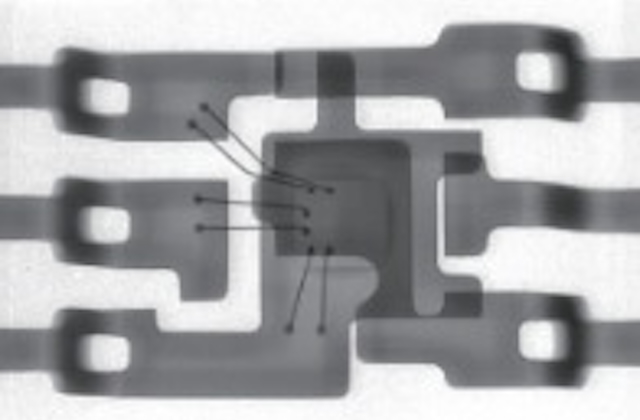

Ball Grid Arrays (BGA) and Bonding Wire Inspection

Ball Grid Array (BGA) components and bonding wires are critical yet challenging to inspect due to their small size and intricate positioning. Gulmay’s microfocus X-ray technology provides exceptional clarity for BGA and bonding wire inspection, enabling manufacturers to identify issues such as misalignment, bridging, or weak connections. This enhanced inspection capability supports the quality assurance of advanced electronic components and assemblies within the electronics industry microfocus inspection landscape.

Integrated Circuit (IC) and Surface Mount (SMT) Inspection

Integrated circuits (ICs) and surface-mounted devices (SMDs) require high levels of precision, as any fault within these components can lead to device failure. Gulmay’s microfocus X-ray systems are designed to inspect ICs and SMT assemblies thoroughly, detecting minute flaws in complex structures. By offering high-resolution, real-time imaging, our electronics industry microfocus inspection solutions ensure these components meet rigorous quality standards essential in high-stakes electronics manufacturing.

IGBT Substrate and Module Inspection

IGBT (Insulated Gate Bipolar Transistor) substrates and modules are vital in power electronics, requiring faultless performance under extreme conditions. Gulmay’s microfocus X-ray inspection allows for in-depth analysis of IGBT substrates, detecting potential defects within layers and connections that could compromise functionality. Electronics industry microfocus inspection for IGBT modules ensures product reliability, an essential factor in automotive, aerospace, and industrial applications.

The Gulmay Advantage in Electronics Industry Microfocus Inspection

With over four decades of expertise, Gulmay’s microfocus X-ray technology provides industry-leading solutions for electronics industry microfocus inspection. Our systems deliver precision, adaptability, and unparalleled imaging quality, empowering manufacturers to maintain the highest quality standards. Choosing Gulmay means investing in innovative inspection technology that elevates quality control across every sector of electronics manufacturing.

For more information on how Gulmay’s microfocus X-ray solutions can enhance inspection processes for your electronics manufacturing needs, contact us today.

Other Microfocus Xray Inspection Applications

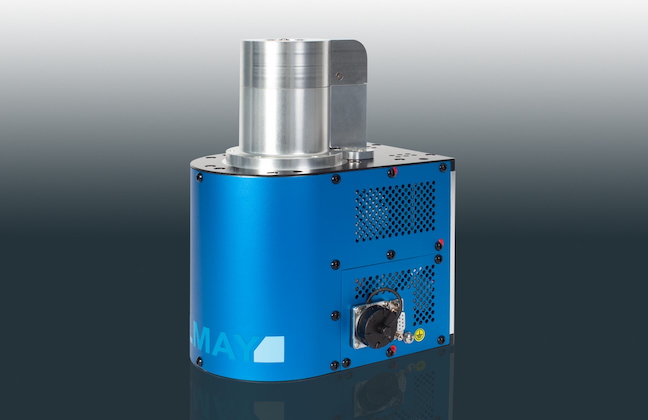

Gulmay Generators for Electronics Industry Microfocus Inspection

UC Series X-ray Generators

Gulmay’s Microfocus generator line up has grown to include generators ranging from 65kV up to 320kV. Read More

GMF Series Integrated Sources

GMF series microfocus X-ray sources offer outstanding performance and reliability in a compact package.Read More