Whether in R&D or production-line testing, our integrated microfocus xray sources provide outstanding performance, empowering manufacturers to produce safer, longer-lasting, and more efficient energy storage solutions.

Enhancing Safety and Efficiency in Battery Production

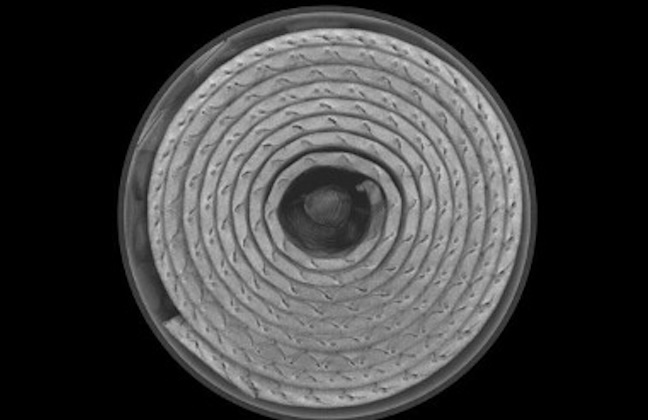

Battery technology demands the highest safety standards, as undetected flaws can lead to reduced performance or even hazardous failures. With Gulmay’s X-ray integrated microfocus sources, manufacturers can ensure the integrity of internal components such as electrodes, separators, and current collectors. This level of inspection reveals voids, inclusions, and contamination that could compromise the battery’s quality, durability, and safety. By using our X-ray technology, manufacturers can safeguard product integrity and significantly reduce the risk of costly recalls or safety issues in the field.

Unmatched Precision for High-Resolution Imaging

Gulmay’s microfocus X-ray sources offer the precision and reliability required for the most demanding production requirements. A JIMA resolution of less than 5 microns with a focus to object distance of 10mm allow provides the high magnification required to identify the smallest of imperfections. With a sub-80 micron JIMA resolution achieved at 65W, the GMF130 microfocus source is capable of identifying imperfections within dense battery materials, such as lithium-ion and solid-state designs, giving detailed insights that other inspection methods may miss. This critical inspection ability ensures that batteries are manufactured to exacting standards, with every layer and component meticulously evaluated for optimal performance.

Optimising Production with Real-Time Analysis

Our X-ray microfocus sources provide real-time imaging, allowing for rapid and accurate assessments during the manufacturing process. This instant feedback enables manufacturers to identify and rectify issues on the production line, reducing waste and maximising throughput. The non-destructive nature of our X-ray technology also means batteries can be inspected without compromising their functionality, supporting a seamless workflow and optimising production efficiency.

Supporting Innovation in Battery Design and Production

As battery technology evolves, with advancements in energy density, fast-charging capabilities, and thermal stability, inspection requirements become increasingly complex. Gulmay’s X-ray sources adapt to these emerging needs, supporting innovation in next-generation battery designs. Our microfocus systems offer flexibility and scalability, making them suitable for a range of battery sizes and configurations, from single cells to complete packs. This adaptability ensures manufacturers remain equipped to meet both current and future demands in the dynamic battery sector.

Why Choose Gulmay for Microfocus Xray Battery Inspection?

With decades of experience in X-ray generator technology, Gulmay stands as a trusted partner for precision inspection solutions across multiple industries. Our GMF microfocus sources enble high-definition imaging, speed, and reliability, making them a valuable tool for manufacturers striving for excellence in product quality and safety. Gulmay’s commitment to innovation and customer support ensures that our X-ray sources not only meet today’s inspection requirements but are also ready to support the demands of tomorrow’s battery technologies.

For more information about Gulmay’s X-ray microfocus sources for battery inspection, please contact us to learn how our solutions can enhance your production quality and safety.

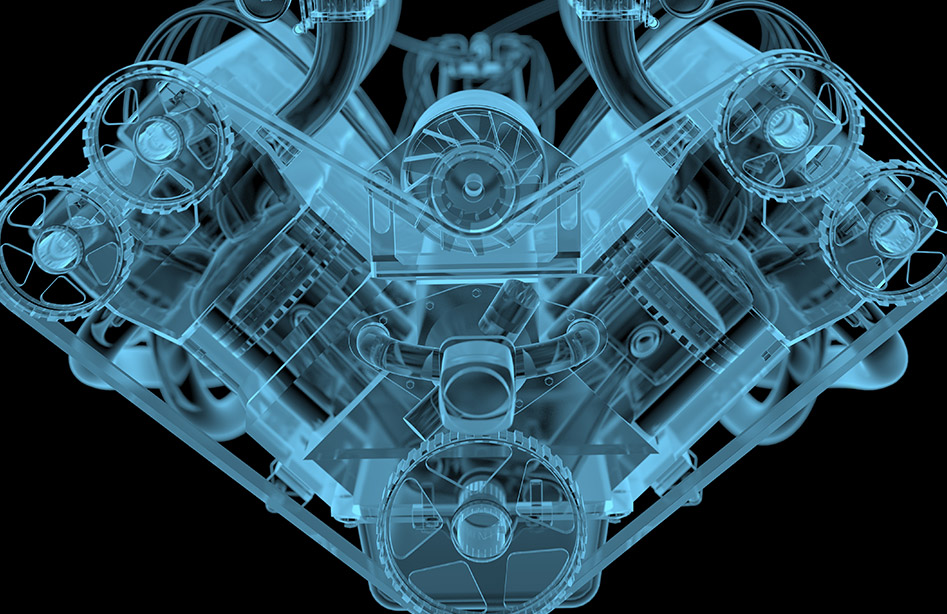

Other Microfocus Xray Inspection Applications

Gulmay Generators for Microfocus Battery Inspection

UC Series X-ray Generators

Gulmay’s Microfocus generator line up has grown to include generators ranging from 65kV up to 320kV. Read More

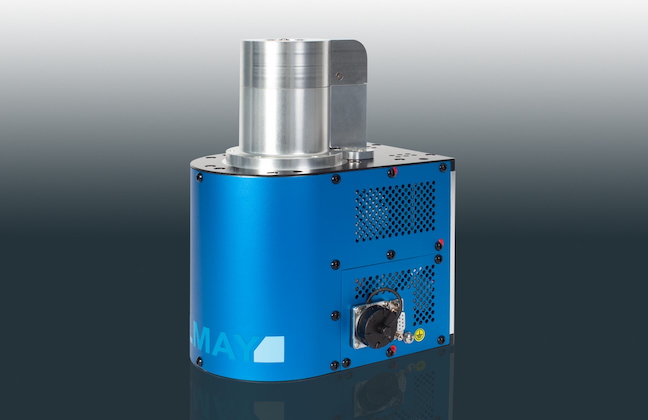

GMF Series Integrated Sources

GMF series microfocus X-ray sources offer outstanding performance and reliability in a compact package.Read More