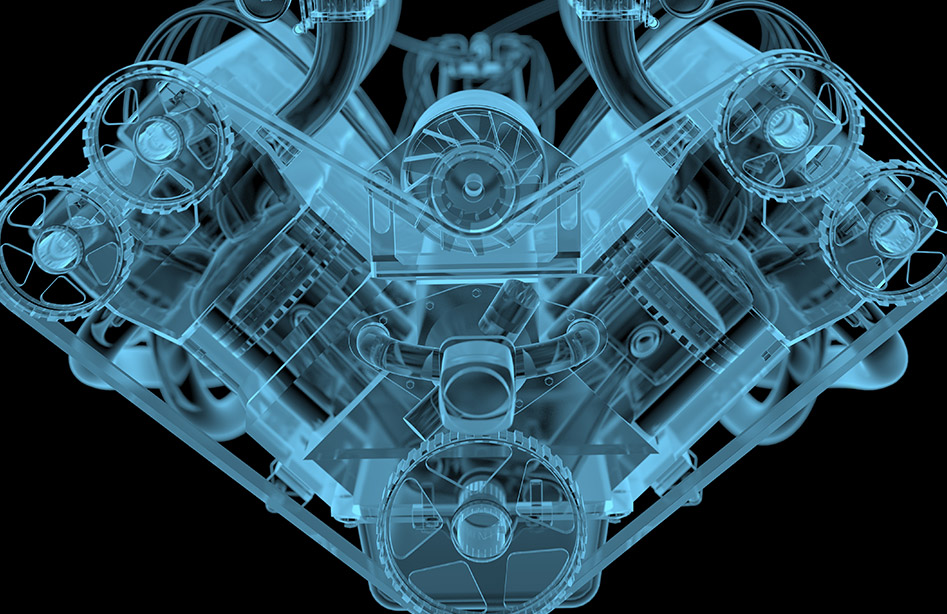

X-ray Thickness Gauging Systems & Applications

X-ray thickness gauges measure the thickness of a wide range of materials, including metals, plastics, paper, and films. In the metals industry, thickness gauges are used to monitor the thickness of steel slabs, billets, or coils during the hot rolling process. These gauges provide real-time measurements, ensuring that the steel is rolled to the correct dimensions and tolerances.

In cold mills, thickness measurement systems are employed in downstream processes related to cold rolling in the steel and aluminium manufacturing industry. Cold mills are used to reduce the thickness of strips or coils through a series of rolling processes at ambient temperature. X-ray technology plays a crucial role in quality control and inspection during various stages of steel processing, including cold rolling.

Thickness gauging systems offer real-time measurements, allowing for rapid process feedback and control. X-ray thickness gauges can provide highly accurate thickness measurements, even for thin or low-density materials. Steel gauging applications are notoriously demanding. They require power supplies with both high power and high stability to work reliably over a wide range of operating conditions.

Working in partnership with the leading manufacturers of steel gauging systems, Gulmay has developed air and water-cooled x-ray generators with the ruggedness and durability needed to operate reliably in the harshest of environments. With their unique design features, Gulmay products are found in many steel manufacturing plants around the world.

X-Ray Generators for the Gauging Industry

Gulmay’s line of water and air-cooled generators offers the ruggedness and durability required to operate reliably in the harshest environments. With their unique design features, Gulmay X-ray generators are installed in many steel manufacturing plants around the world.